Introduction

This article provides an overview of the features you can use in Canvas for Palette printing and more.

-

-

Transform models for multi-material printing by painting them in Canvas. This is best with models that are single-body or comprised of one model.

-

Painting allows for colored regions to be created directly on the model.

-

Painting will not separate the model into multiple STLs, but the painted regions will be recognized as regions for color transitioning after slicing.

-

Stamping allows for images to be placed on the model. Check out these tips on how to get better stamps onto models.

-

Stamping behaves like an image on a light projector against an object. The stamp is best placed on flat faces of the model, and will "wrap" around the geometry. Multiple stamps can be used on a model.

-

Painting and stamping are available when you select an ungrouped model, and click Paint Selected.

-

-

-

Custom supports allows for support placement to be selected and placed manually, minimizing surface defects.

-

Adding custom supports is similar to painting, where regions and polygons on the model can be selected. Supports will generate directly below the painted region towards the bed.

-

Custom supports are available under Project Settings > Supports > Support Method: Custom > Configure Custom Supports

-

-

-

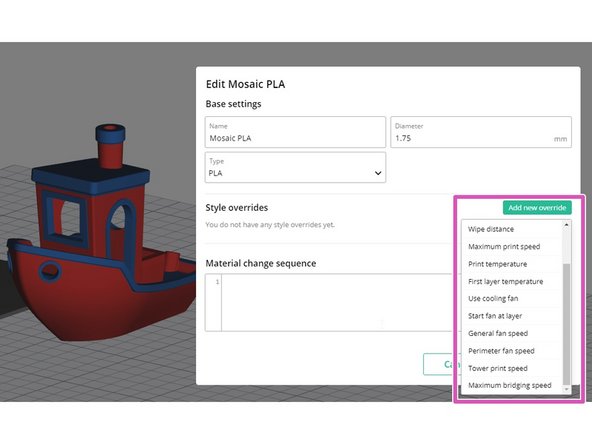

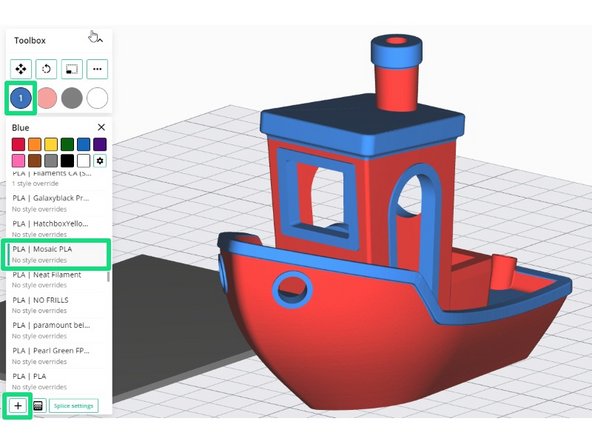

Create custom material profiles that can be selected for each input drive on Palette.

-

Style overrides allows certain settings to be used when that material profile is selected by a drive.

-

Having custom material profiles allows for each filament brand or different finishes to have its own settings.

-

Manage material profiles from the main menu, or Open Project > Select Tool/Color > Select or Add New Material.

-

-

-

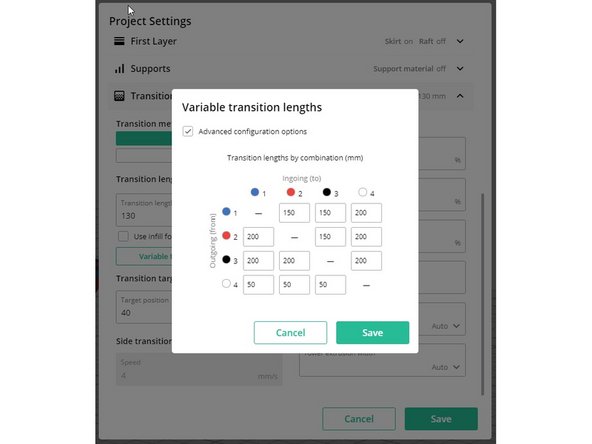

Variable transition lengths allows for purge lengths to be specified between drives and colors used, assisting with reducing color bleed during printing.

-

Use variable transitioning to purge more for strong colors such as black and red, and reduce the purge amount when transitioning from light colors.

-

Variable transitioning is available when you open a project > Project Settings > Transition > Variable Transitions.

-

-

-

Side transitioning allows material to be purged off the bed or on a specified coordinate. This method of color transitioning can help reduce print time and waste.

-

Side transitioning is compatible with BigBrain3D when using Palette in connected mode.

-

Side transitioning firmware settings (purge location) are available when you edit a printer profile. Transition and purge amount settings are available under Project Settings > Transition > Side transition.

-

-

-

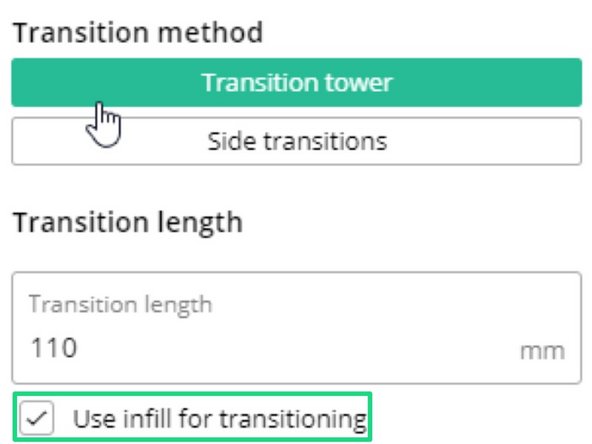

Infill transitioning uses available infill as part of the transition allowing you to reduce the tower size, overall waste, and print time.

-

Canvas will attempt to use the most recent part of the infill as part of the transition sequence.

-

This method is not recommended if soluble supports are used in the print.

-

This is available under Project Settings > Transition > Use infill for transitioning

-

-

-

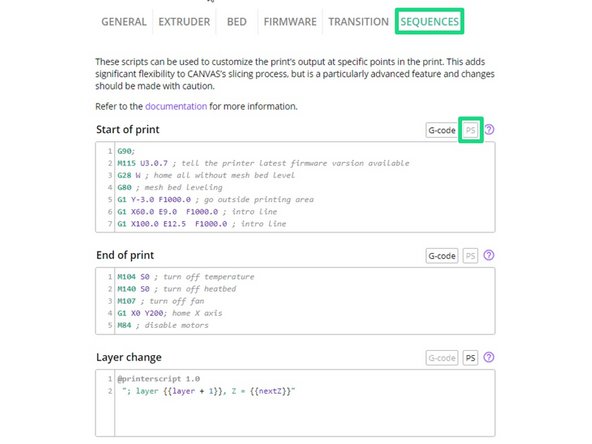

PrinterScript allows for advanced sequencing in starting scripts, ending scripts, side transitions, layer changes and material changes.

-

Here's a tutorial on how PrinterScript can be used to add a pause when a layer is reached, in order to do a filament change. This expands the number of colors used in the print.

-

This is available under Printer Profiles > Select/Edit Printer Profile > Edit Printer > Sequences.

-

-

-

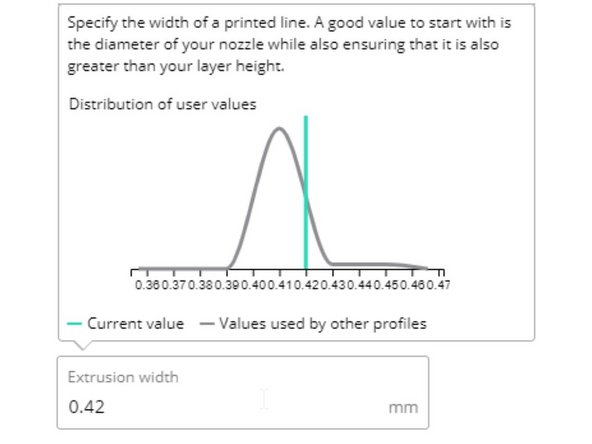

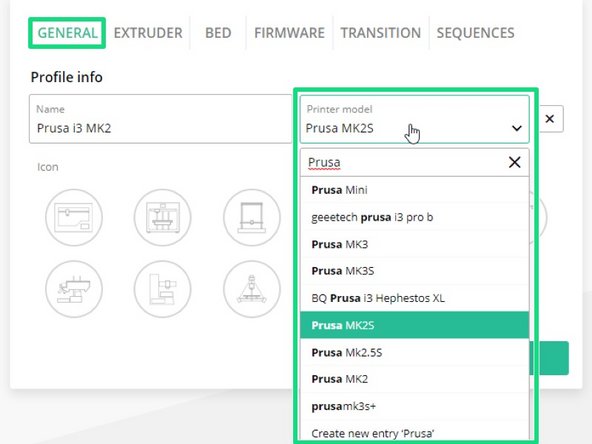

Printer tagging aggregates data from other printer profiles. This helps inform what values or settings to use in the printer profile.

-

Select from existing printer models, or create a new entry if the printer is not available.

-

Printer tagging is available under Printer Profiles > Select/Edit Printer Profile > Edit Printer > Printer Model.

-

-

-

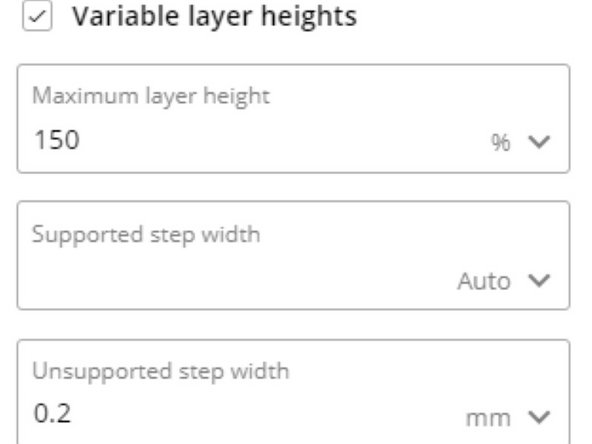

Variable layer heights allows the slicer to automatically and smoothly change between a minimum and maximum layer height.

-

Minimum layer heights are used where parts have shallow slopes, such as on top of a sphere.

-

Maximum layer heights are used for steep slopes or vertical walls.

-

This is available under Project Settings > Layer > Variable Layer Heights.

-

-

-

Sharing allows for printer profiles, style and setting profiles, material profiles and models to be shared with others.

-

Enabling sharing allows others to import the above mentioned with a URL.

-

Sharing is available within an open project, or from the Projects dashboard.

-

Have a feature request or want to share feedback? Please visit Canvas on Github or our contact page. Thank you!

Have a feature request or want to share feedback? Please visit Canvas on Github or our contact page. Thank you!

Cancel: I did not complete this guide.

5 other people completed this guide.