Introduction

Failures to load are typically caused by an obstruction in the filament pathway or Print Head, preventing filament from loading into the Hot End.

In rarer cases, they can be caused by a communication failure at the Print Head, causing the 'Failed to load' error message to be shown even though filament is loaded correctly.

-

-

Follow our Filament Pathway Inspection and Clearing article to check the entire filament pathway for obstruction.

-

Feed filament manually through the pathway and ensure that it can reach the Print head. Check also that the Print Head is clear of filament.

-

-

-

Check the nozzle for any filament build up. Heat the nozzle and clean using a wire brush as needed.

-

Check if the nozzle is visibly bent or damaged. If so, you may need to replace the Hot End.

-

With a clean nozzle, check that the Hot End can extrude filament properly. Load filament and extrude using the on-screen controls.

-

-

-

If the entire filament pathway is clear and the Hot End extrudes properly, but you still receive 'Failed to load' errors when you start printing, this likely indicates a Print Head communication issue.

-

Following the steps from our Print Head Disconnection article.

-

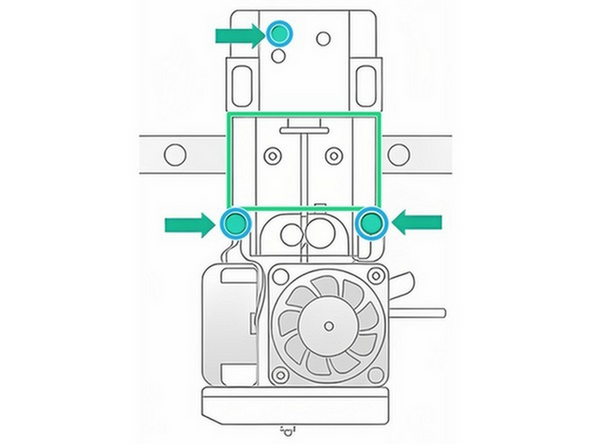

Try re-installing the Print Head, as well as using a different Print Head. Inspect the Fixed End PCB and FFC for damage.

-

Contact Mosaic Support at support@mosaicmfg.com with your findings, as replacement components may be needed.

-