Introduction

Before starting a print, Element performs a bed levelling check, to ensure that the bed is ready for printing.

A failure in this process could have several causes. These include: an incorrectly positioned Print Bed, a blob on the nozzle, a homing error, or a build plate that is not flat.

-

-

Element users should check that the Print Bed is positioned completely flat on the build plate, and that the edge is not caught on either side, as in the picture.

-

Array users can skip this step.

-

-

-

A common cause of bed levelling failures is a blob on the nozzle. This prevents the nozzle from contacting the bed properly during bed levelling.

-

Check the nozzle for any filament build up. Heat the nozzle and clean using a wire brush.

-

If you are consistently seeing blob forms on the nozzle, run through our Densifier Alignment and Troubleshooting guide

-

Check if the nozzle is visibly bent or damaged. If so, you may need to replace the Hot End.

-

-

-

Follow our Z Homing Error article to check that the bed moves all the way to the top and contacts the nozzle during Z homing.

-

If the bed contacts either the Transition Container or Densifier, follow the steps in the above article to rectify this. Contact Mosaic Support for further help if needed.

-

-

-

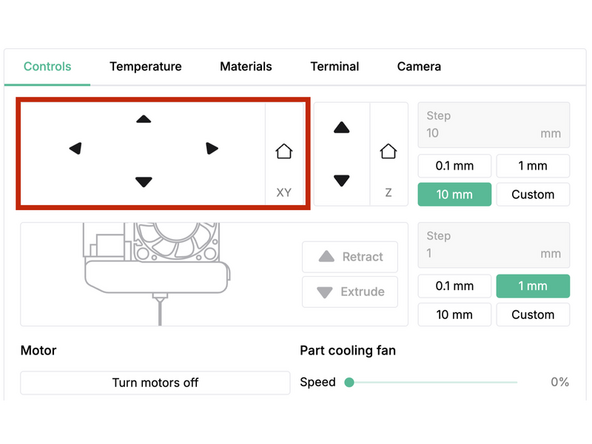

Following our XY Homing Error article to check that the Print Head homes correctly.

-

If you see homing errors, inspect gantry alignment and check belt tension, as shown in the above article. Contact Mosaic Support for further help if needed.

-

-

-

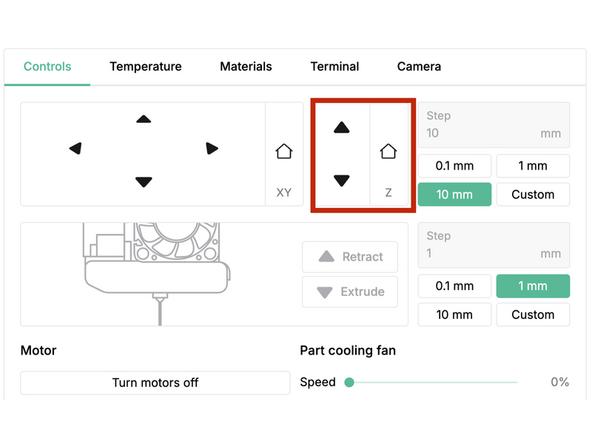

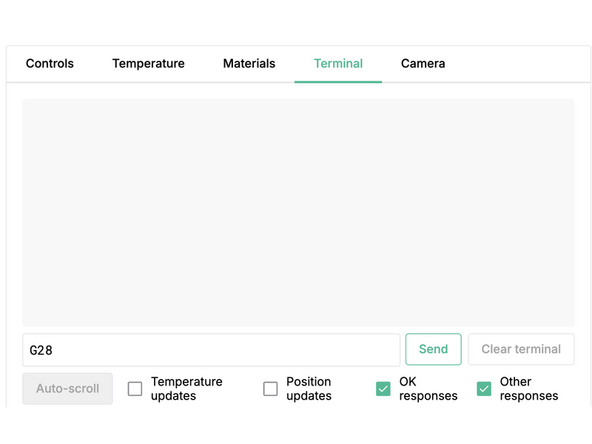

If bed levelling failures persist after following steps 1-4, navigate to the Terminal tab in Canvas device view.

-

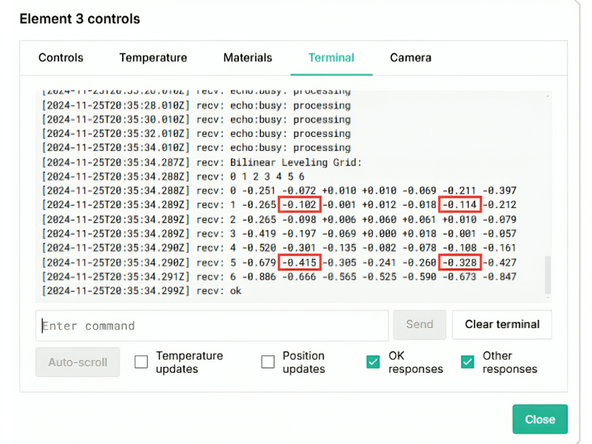

In the Terminal, input G28 and press send, followed by G29 V4. This will generate a 49 point levelling grid, representing the measured height of the bed at each point. The first row 0 represents the front of the bed.

-

The 4 highlighted points should be within +/-0.2mm of each other. If not, please share this data with support@mosaicmfg.com for guidance on next steps.

-

Cancel: I did not complete this guide.

One other person completed this guide.