Introduction

In this guide you will learn how to replace the cutter wheel assembly on Palette 3 and Palette 3 Pro.

Tools

Parts

No parts specified.

Video Overview

-

-

Remove Palette's top lid.

-

Using the provided Torx screwdriver, remove the 4 screws on each corner of the substructure.

-

-

-

Remove the IO plate cover from the unit, by pulling the tab on the Ethernet port. The IO plate cover is snap-fit to the unit and can be placed back easily.

-

Gently lift and remove the substructure from the bottom casing.

-

You'll now be able to replace the main board, fans, and other components.

-

-

-

Remove Ingoing Driver Cover B by unscrewing the two thumbscrews, and lifting the acrylic cover.

-

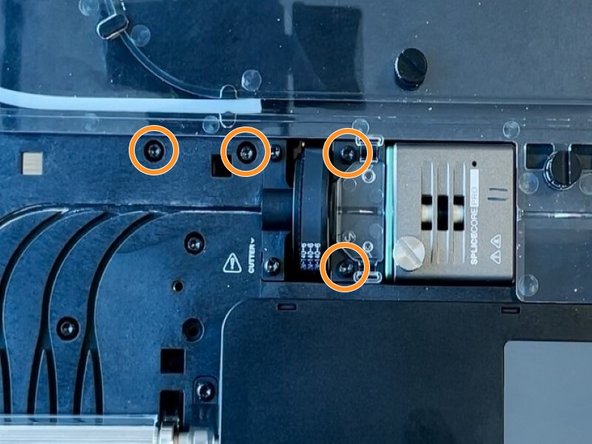

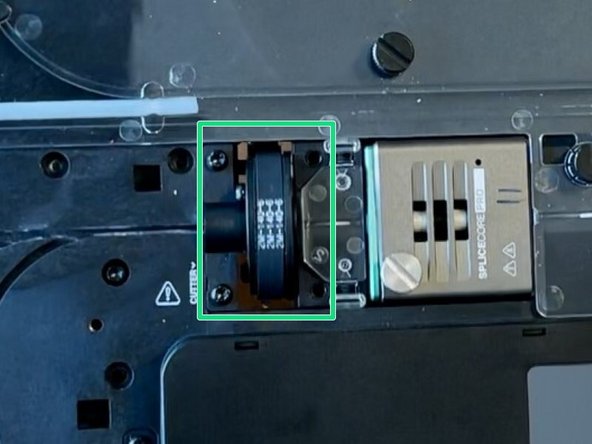

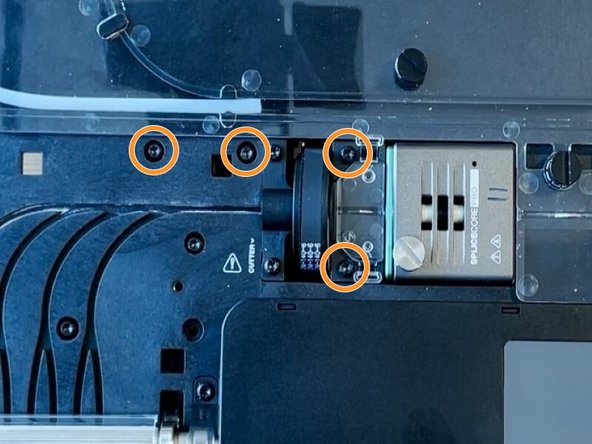

Using the torx screwdriver, remove the two screws holding the cutter wheel assembly and the two screws holding cutter motor.

-

-

-

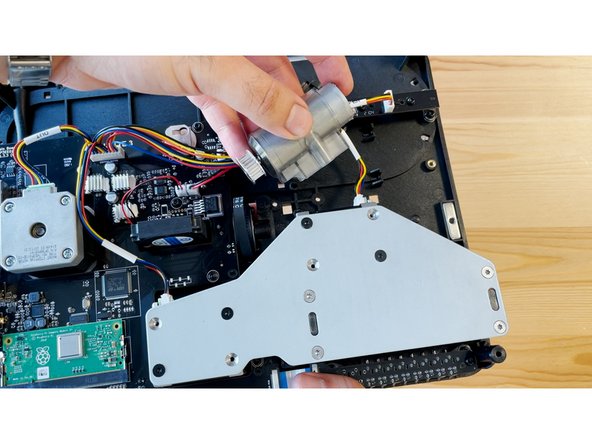

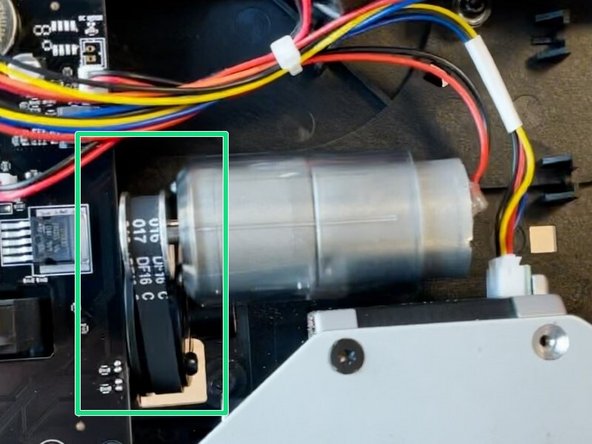

Flip the substructure over, and remove the cutter motor from its position. Keep the motor wiring plugged in.

-

Set the motor aside, and hold the motor in place while flipping the substructure over again to return to the front of the unit.

-

-

-

Lift the old cutter wheel assembly from the substructure. Set the cutter belt aside.

-

Place the old cutter belt onto the new cutter wheel assembly, before returning back into the unit.

-

-

-

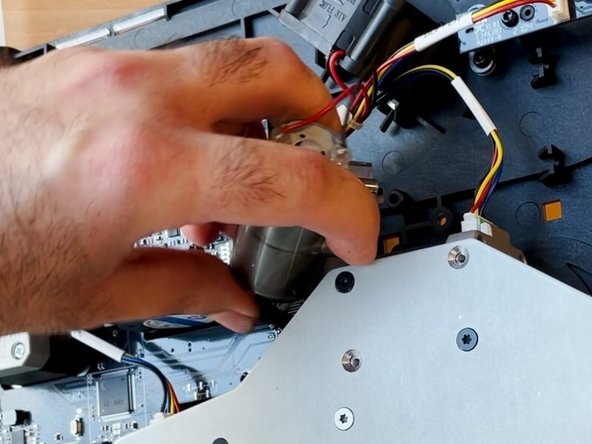

Hold the cutter wheel assembly while flipping the unit to face the bottom of the substructure.

-

Insert the gear end of the motor into the belt, and then re-align the pins on the motor to its original position on the substructure.

-

-

-

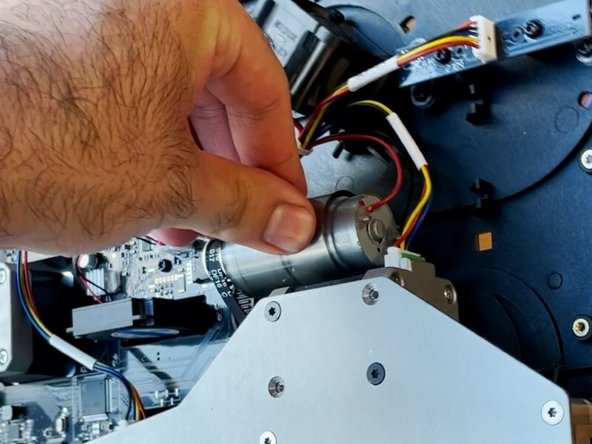

Check that the belt is around the cutter wheel sprocket.

-

Holding the motor in place with your hand, replace the two screws to hold the motor in place. Proceed with the other two screws to hold the cutter wheel assembly.

-

For the two screws holding the cutter wheel assembly, avoid over-tightening to prevent threads from stripping.

-

Check that the cutter wheel assembly and motor are back in place, and that the belt is both on the cutter wheel sprocket, and motor.

-

-

-

Place the ingoing drive cover back in place and secure with the two thumbscrews.

-

Place the substructure back into the bottom casing, and secure back into place with the four screws.

-

Snap the IO plate cover back into place.

-

If you have any additional questions, please send us a message at support@mosaicmfg.com

If you have any additional questions, please send us a message at support@mosaicmfg.com

Cancel: I did not complete this guide.

One other person completed this guide.