Introduction

Element will be unable to start a print if leftover filament remains in the Print Head, or the nozzle is clogged.

Removing filament, heating and cleaning the nozzle, and testing extrusion is typically sufficient to start printing again. In some cases, a hot pull is necessary to clear a nozzle clog.

In the case of a bad clog or filament build up, the Hot End may need to be replaced.

-

-

Take off the Print Head cover, and inspect the Print Head and PTFE tube. If filament is still in the Print Head, it can be cleared using Controls > More > Clear Filament Path

-

If filament cannot be cleared using the controls, it can be cleared manually: heat the nozzle to the printing temperature of the material, then disconnect the tube from the Print Head using the quarter-turn mechanism at the top. You should be able to pull the filament out of the Print Head

-

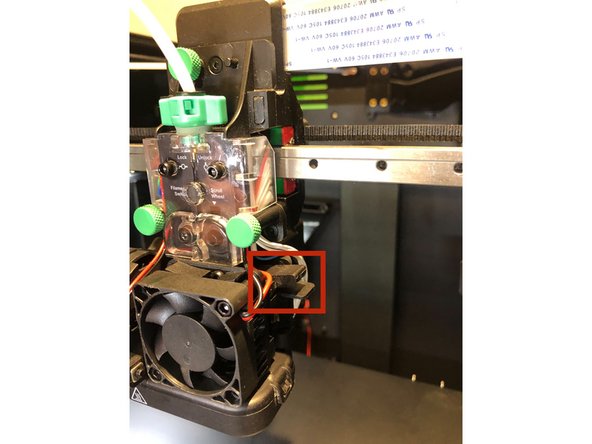

Press down on the green idler arm on the right side of the Print Head, while pulling up on the filament

-

-

-

Check the nozzle for any filament build up. Heat the nozzle and clean using a wire brush as needed.

-

Check if the nozzle is visibly bent or damaged. If so, you may need to replace the Hot End.

-

With a clean nozzle, check that the Hot End can extrude filament properly. Load filament and extrude using the on-screen controls.

-

-

-

If the nozzle is unable to extrude, it may be clogged. You can attempt a hot pull to clear it.

-

Heat the nozzle to the temperature of the filament inside, or slightly over. Manually insert a piece of filament into the Print Head, and push it down into the Hot End. Let it sit there for a minute.

-

Push the idler down, on the right side of the Print Head, while pulling the filament up. Be careful of hot filament - you can use pliers to pull upwards.

-

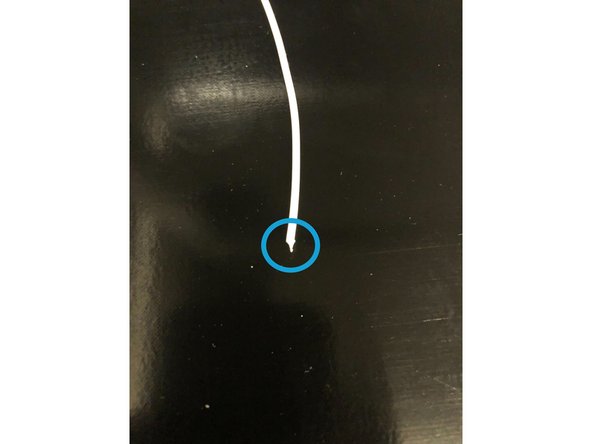

If the end of the filament has a conical shape, this indicates you cleared the clog.

-

If a hot pull is unsuccessful, you may need to replace the Hot End.

-

Cancel: I did not complete this guide.

One other person completed this guide.