Introduction

In this guide you will learn how to:

- Change the loading offset, historical modifier, and outgoing tube length

- Change your printer name

-

-

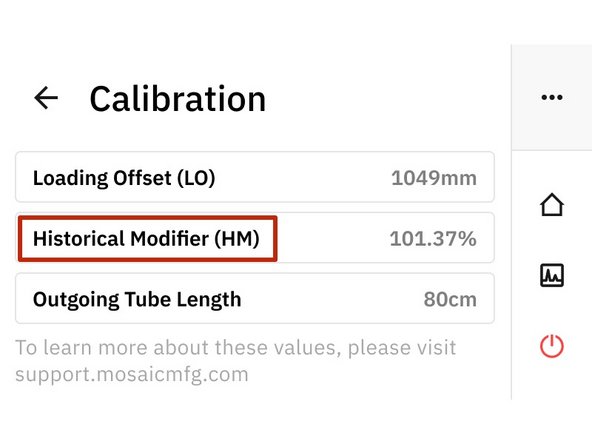

Go to Home Screen > Printers > Select Printer > Edit Calibration Data to view and change the following:

-

Loading Offset (LO). This represents the overall length from Palette's output to the printer nozzle. It includes the outgoing tube length, extruder length, and any other bowden assemblies the filament must travel to reach the nozzle.

-

Historical Modifier (HM). This is the average pings over time.

-

Outgoing Tube Length. The tube used between Palette and the extruder.

-

Learn more about loading offset and historical modifier and how they are used for calibration.

-

-

-

Measure Loading Offset (LO) values

-

Part of the loading offset includes the distance between where the tube clips into the extruder and the nozzle. If the hot end was changed, or if the printer was changed between direct drive to bowden, this length can be modified.

-

Enter new Loading Offset measure and save.

-

-

-

Calibration > Historical Modifier

-

The historical modifier value will be logged here as the printer profile continues to tune from saving print data.

-

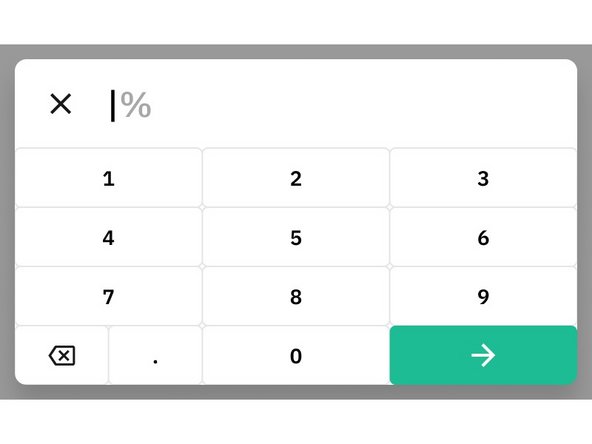

This historical modifier also represents the ping average, and the percentage can be manually edited if necessary.

-

-

-

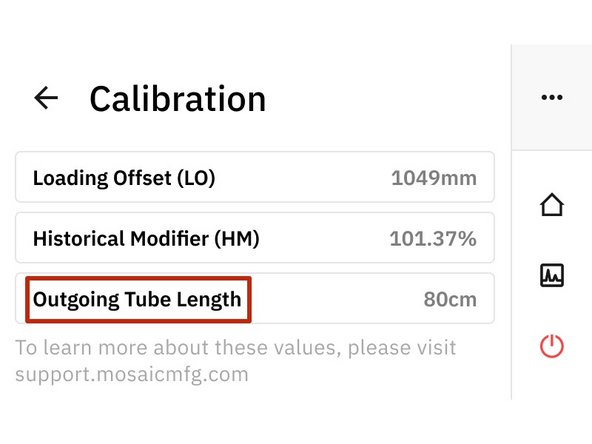

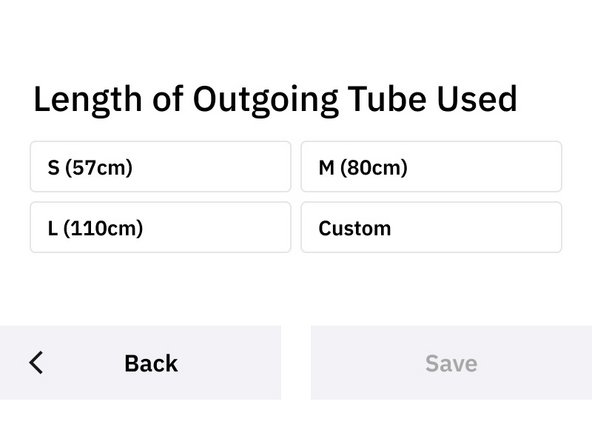

Calibration > Outgoing Tube Length

-

If the tube being used between Palette and the printer is changed, enter the new length here.

-

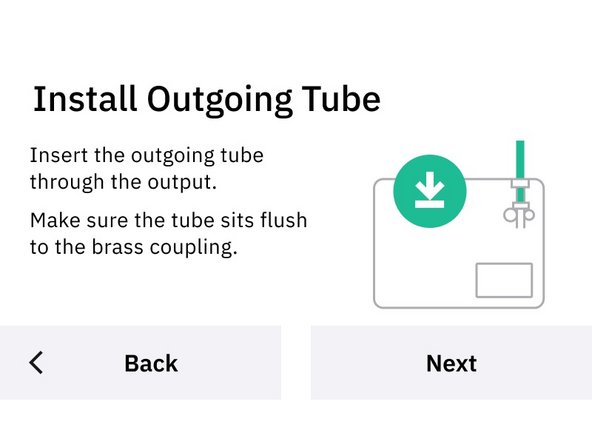

Install Outgoing Tube following the steps from the printer setup.

-

Enter the length of the outgoing tube used, and save.

-

S(57cm), M(80cm), L(110cm), or enter a custom length.

-

-

-

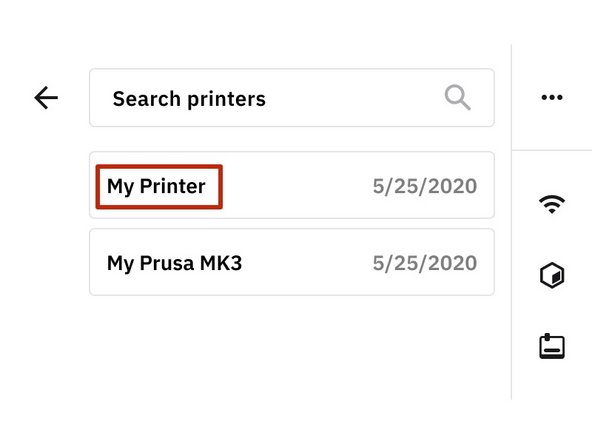

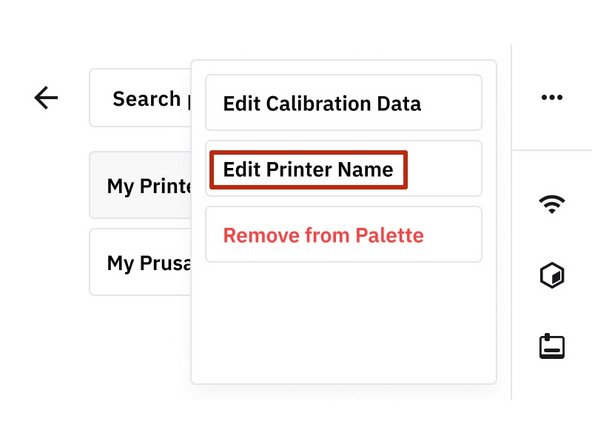

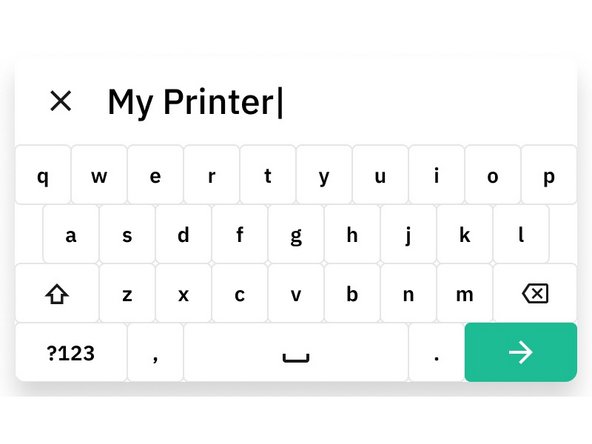

Access the status bar by tapping the 3 dots in the right corner. Tap Printer > My Printer > Edit Printer Name

-

Rename the printer and save.

-

If you have any additional questions, please send us a message at support@mosaicmfg.com

If you have any additional questions, please send us a message at support@mosaicmfg.com

Cancel: I did not complete this guide.

7 other people completed this guide.