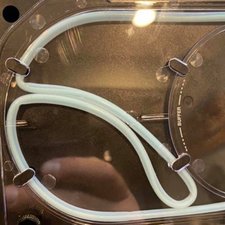

Symptoms

The PTFE tube inside the buffer area is bent in some areas.

In some cases you may also see the screen display error 131, which can happen when loading for a print or during a print.

Potential Causes

- During initial loading, the outgoing tube on the extruder may be inserted into the tube clip before the filament from Palette is loaded into the extruder. By not having the filament loaded into the extruder, as Palette drives filament forward the tip of the filament may reach an obstruction.

- A broken splice gets driven through the buffer tube. As the solid length of filament gets driven forward and overlaps with a fragment or broken piece, the obstruction causes the filament to not drive to the output.

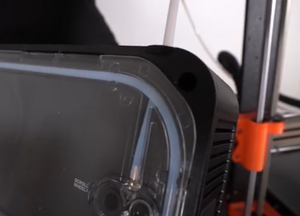

- The outgoing tube is not pushed all the way through and around the brass retainer on Palette 3's output. Filament may be getting caught on this path or section which is unguided by the PTFE.

Troubleshooting

For each of the potential causes above...

- Outgoing tube inserted into tube clip during loading: Prevent the tube from buckling by following the loading prompt to insert filament into the extruder so it is engaged by the gear, before inserting the outgoing tube into its clip.

- Broken splice or filament fragment: Examine the splices, or if the filament spool is brittle. If the splice looks like it was fused but was broken, it can be improved through splice tuning by applying more heat. If the splice looks like no heat was applied at all (clean break between materials), please examine the splice core's POGO pins for any damage.

- Outgoing tube not fully inserted: before starting Palette for printing, check that the outgoing tube is fully inserted and around the brass retainer.

How to remove and replace buckled tube

The PTFE can be removed to clear any obstructions before putting back in place, or if it is severely bent, it can be replaced altogether following this buffer tube maintenance guide.